Kassel becomes the Volkswagen Group's e-engine centre

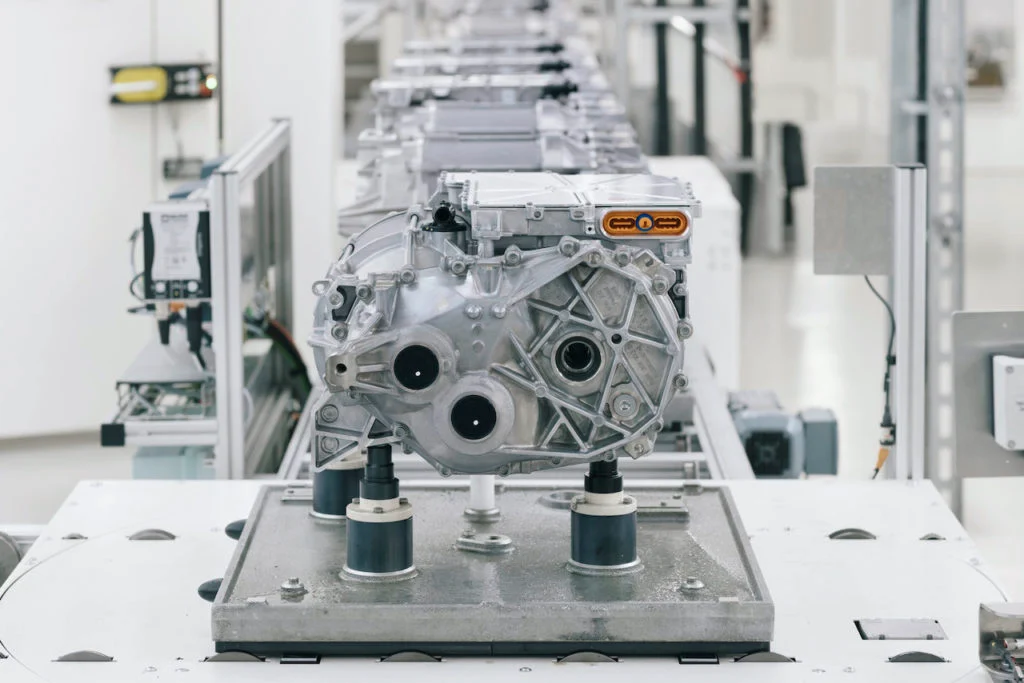

The Volkswagen Group Components site in Kassel will become a key supplier for e-mobility: the plant will accelerate the transformation started in 2015 and focus its product portfolio on tech components for electric cars at full speed, VW said in a recent announcement. The number of the current 18 production lines for e-motors and other e-components is to double in the next 4 years.

In the long term, Kassel is to become a pure E-plant and a system provider for E-mobility: As a Group-wide competence centre for e-drives, Kassel will develop the electric powertrain of the future Scalable Systems Platform (SSP) in cooperation with the Volkswagen and Audi brands. Volkswagen Group Components is investing around 1.2 billion euros in the site for these steps up to 2026, with more than two-thirds of the sum being spent on the development and production of e-components.

The next-generation electric powertrain is to set completely new standards in terms of efficiency, performance and volume. To achieve this, Volkswagen is going into in-house development: in addition to the e-drive with rotor and stator, the pulse inverter will also be developed and produced in-house in future. As the central control unit, it is the brain of the powertrain and a key to lower power consumption, longer ranges and higher performance. The first in-house developed pulse inverter for the modular e-drive system (MEB) is scheduled to start production at the site in 2025. Innovative manufacturing processes developed at the site have been used for its industrialisation.

The second major area of expertise at the Kassel plant is the production of highly integrative platform parts. With the know-how of the experts in Europe's largest light metal foundry, an innovative process for structural part casting has been developed on existing equipment. This will enable the production of large components on medium-sized die-casting machines. The first large cast component in the project was cast for a rear car. The 1.6 m x 1.5 m component replaces 33 individual parts compared to conventional car body production. Kassel is also able to supply the SSP platform with large castings and other highly integrative platform parts, thus contributing to the reduction of production time for future e-vehicles.